Global Spare Parts Search

Stop searching, start finding

Reducing inventories. Increasing availability.

/Logo%20Banner/Nestle%20Logo%20Banner.png?width=300&name=Nestle%20Logo%20Banner.png)

How to safely reduce spare parts inventories?

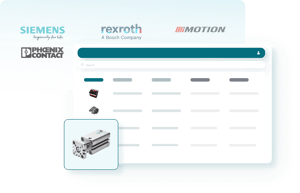

SPARETECH identifies synergies at the push of a button. In the first step, SPARETECH's solution ensures transparency by uniquely identifying spare parts through state-of-the-art technologies from the fields of semantic data management, Big Data and automated data processing. In the second step, duplicates, discontinuations and common parts across locations are made visible and original manufacturer product information is added. The result is a complete and error-free database.

%20(1).png?width=300&name=Data%20Management_Matching_en%20(5)%20(1).png)

"Thanks to the efficient and reliable data preparation of over 30,000 material numbers, we were able to immediately start reducing inventories in all plants."

RENÉ HACKBART | DIRECTOR MAINTENANCE AT ELRINGKLINGER

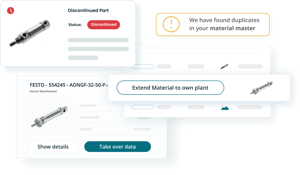

Identify duplicates to stop any double stocking

Cleaning up your data, especially removing duplicates from the system can be a lengthy process, hence it is important to reduce unnecessary high stock levels. SPARETECH identifies duplicates by a push of a button. With that information at hand the process of removing duplicates and definition of leading material numbers can be started. Get the full guide on how to find and remove duplicates in your material master.

Always up-to-date about discontinued products

By providing information on discontinuations and successor products from manufacturers we enable manufacturing companies to stock spare parts

smarter. With obsolescence information at hand, you can prevent costly

purchases of obsolete items. This way you can always be sure to have the

right spare parts in stock in case of a machine failure.

Identify your real demand based on availability

Optimizing stock levels based on part availability is a strategic approach to efficient inventory management. By making data-driven decisions, you can ensure that essential parts are on hand when needed, while stock levels can be kept at an optimum. SPARETECH shows you if a needed spare parts is available in your production network and unveils alternative sourcing options. This enables you to always make the best stocking decisions.

Benefits of managing MRO master data with SPARETECH

Benefits of managing MRO master data with SPARETECH

Inventory

Identify duplicates and obsolescence in the material master to sustainably reduce inventories.

Downtime risks

Rely on a data-based approach so that the right part is available in the right place at the right time.

Procurement costs

Compare procurement options of identical parts to achieve savings through substitutes and bundling effects.

Manual effort

Save yourself the online/catalog search and let the software create and update the master data within seconds.

-min.jpg?width=300&name=Resources_Menu%20(3)-min.jpg)