Global Spare Parts Search

Stop searching, start finding

Time is money. Save both.

Industry champions drive business impact with SPARETECH. Boost your efficiency and streamline your MRO processes.

How SPARETECH creates business impact

Managing spare parts data brings significant operational benefits, such as high ROI through optimized inventory management, cost savings and improved operational efficiency. By minimizing scrapping, providing information for procurement and improving resource allocation, companies can achieve growth and competitiveness in their industry.Identify duplicates and obsolescence in the material master to sustainably reduce inventories.

Rely on a data-based approach so that the right part is available in the right place at the right time.

Compare procurement options of identical parts to achieve savings through substitutes and bundling effects.

Save yourself the online/catalog search and let the software create and update the master data within seconds.

Discover your individual savings potential

Tackle the huge challenges in maintenance right and start to reduce your inventory and procurement costs sustainably. We calculate your individual ROI to see how much time, money and other resources you can save by our software solution.

Reduce your working capital to regain free cash flow

SPARETECH helps to optimize your inventory levels and to reduce your working capital. By gaining transparency of available sources and automatic detection of duplicates, you can minimize the risk of overstocking, whilst having a constant overview of available suppliers on the market. This ensures optimal inventory, reduces excess safety stock, and minimizes capital tied up in spare parts, freeing funds for other operational requirements.

An ecological disaster - scrapping spare parts

Manufacturing companies want to avoid machine downtime at all costs. Therefore they maintain extensive on-site spare parts inventories. However, 42% of all purchased spare parts are never used in the life-cycle of the machine and end up scrapped. Beyond the financial costs, this practice represents an ecological disaster, wasting resources, energy, and global supply chain logistics for no value. With SPARETECH, you only get to purchase parts that you actually need, leading to sustainably reduced parts scrapping and CO2 emissions.

Increasing the resilience of the supply chain through data transparency and consistency

SPARETECH provides insights on spare parts data throughout the entire supply chain. The extensive SPARETECH database, comprising millions of original manufacturer and supplier data sets, facilitates seamless communication and reduces dependence on individual suppliers. This supply chain transparency, empowers businesses to maintain operations in the event of supply chain disruptions. In a world where supply chain resilience is key, SPARETECH stands as the go-to solution for efficient and resilient spare parts management.

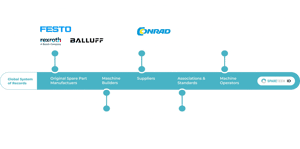

Partners

Platform

Product Data

Related to the topic

Get started today

SPARETECH is the fastest and most reliable way to reduce inventories and costs in spare parts management.

-min.jpg?width=300&name=Resources_Menu%20(3)-min.jpg)