Global Spare Parts Search

Stop searching, start finding

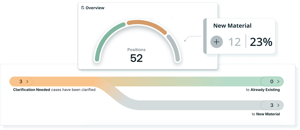

Automated BOM Check

Shorten spare parts list processing time and avoid duplicates by identifying the parts

you already have, and create new materials with original material data.

/Logo%20Banner/Nestle%20Logo%20Banner.png?width=300&name=Nestle%20Logo%20Banner.png)

"By integrating SPARETECH as a standard process for checking spare parts lists for new machines and production lines at the Blaichach plant, we've realized 50% efficiency gains. This has been a game-changer for managing our high volume of new material numbers each year.”

MANUEL LEHMANN | GROUP MANAGER SPARE PARTS & MAINTENANCE PROCESSES AT BOSCH BLAICHACH

Upload your spare part list and let SPARETECH do the line by line analysis. We compare your list with your existing material master and our global catalog to identify what you already have.

Eliminate excess purchases, lower inventory costs, and make the most of existing materials.

Get product suggestions for new list positions with original manufacturer details, then create materials in a few clicks or export via automated data exchange.

Learn how to standardize and govern your material data with

SPARETECH's Digital Workflow.

Identification of your spare parts made easy

New spare parts lists

Provided as Excel, CSV, or other file formats.

BOM Check

Automated check of your spare parts lists against your material master and SPARETECH global catalog.

Clean spare parts lists

Uncover original part manufacturers and find the best supplier for your needs.

Find out what materials you already have across your plants and detect duplicates in the spare parts list.

What our customers say

"SPARETECH checks all new spare parts lists automatically, which means an increase in efficiency of more than 50%. This is how digitalization works!"

/Marcus%20Strauss%20Portrait-1.webp?width=70&name=Marcus%20Strauss%20Portrait-1.webp)

"The SPARETECH algorithm recognizes duplicates better than anything we have seen before. Duplicate stocks are a thing of the past for us."

/Timo%20Thomas.webp?width=300&name=Timo%20Thomas.webp)

"Thanks to the efficient and reliable data preparation of over 30,000 material numbers, we were able to immediately start reducing inventories in all plants."

/Rene%20Hackbert.png?width=300&name=Rene%20Hackbert.png)

Case study

Learn how Idahoan Foods solves manufacturing challenges such as rising costs and inefficiencies with SPARETECH.

-min.jpg?width=300&name=Resources_Menu%20(3)-min.jpg)